Profile Feature |

Typical parameters |

Average Ramp-Up Rate (Ts max to Tp) |

3 °C/second max. |

Preheat Temperature Min (Ts min ) |

150 °C |

Preheat Temperature Max (Ts max ) |

200 °C |

Time (ts min to ts max ) |

60-180 seconds |

Time maintained above Temperature (TL) |

217 °C |

Time maintained above Time (tL) |

60-150 seconds |

Peak/Classification Temperature (Tp) |

260 °C |

Time within 5 °C of Actual Peak Temperature (tp) |

5 seconds |

Ramp-Down Rate |

6 °C/second max. |

Time 25 °C to Peak Temperature |

8 minutes max. |

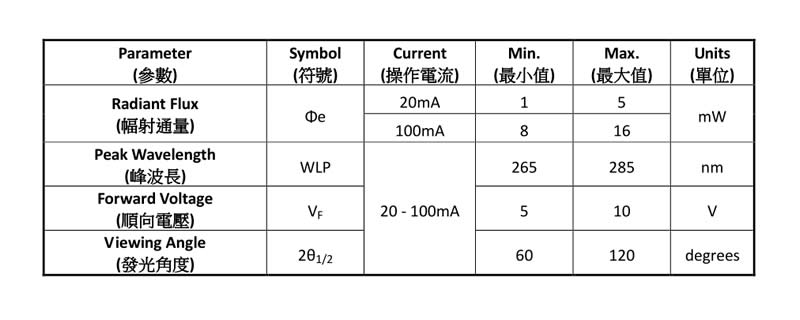

Color |

Order Code |

Peak Wavelength (nm) |

|

Min |

Max |

||

UV

|

UVA-003-275 |

265 |

285 |

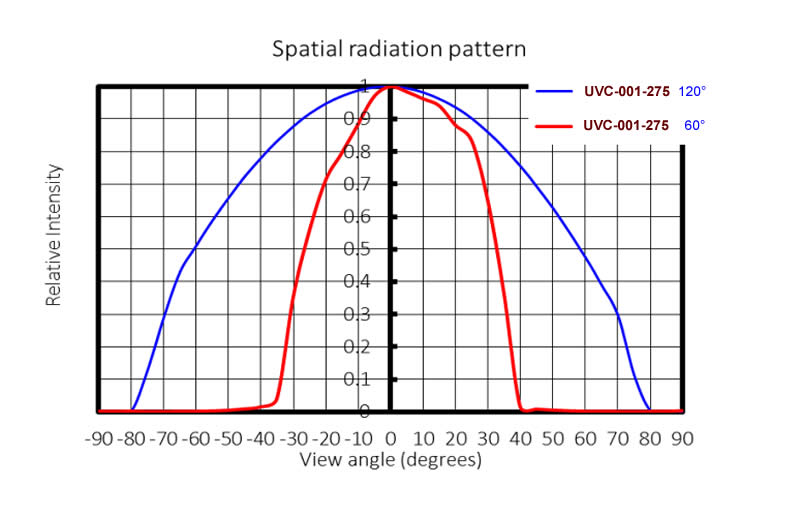

UVA-003-275 - 60° |

265 |

285 |

|