Parameter |

Symbol |

Conditions |

Min. |

Typ. |

Max. |

Units |

Radiant Flux |

Φe |

IF=700mA |

135 |

760 |

mW |

|

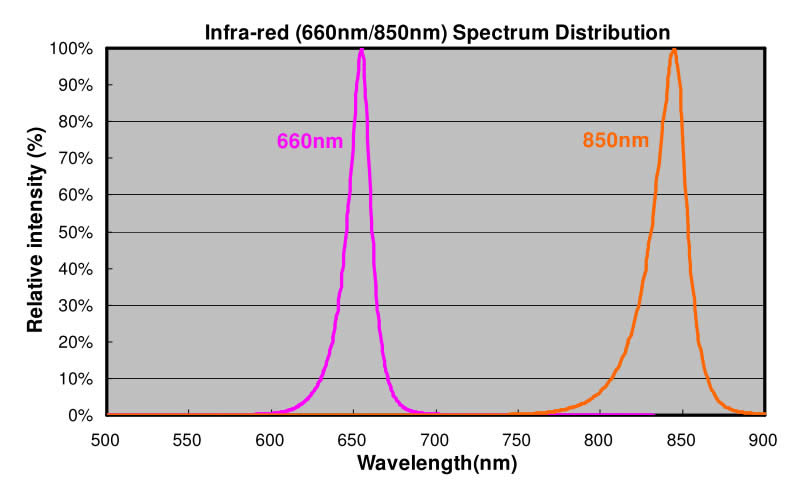

Peak Wavelength |

WLP |

IF=700mA |

640 |

870 |

nm |

|

Forward Voltage |

VF |

IF=700mA |

1.2 |

3.2 |

V |

|

Thermal Resistance JunctionTo Board |

RthJ-B |

IF=700mA |

13 |

°C/W |

||

Temperature Coefficient of Forward Voltage |

ΔVF/ΔT |

IF=700mA |

2 |

mV/°C |

||

Reverse Current |

IR |

VR=5V |

10 |

μA |

||

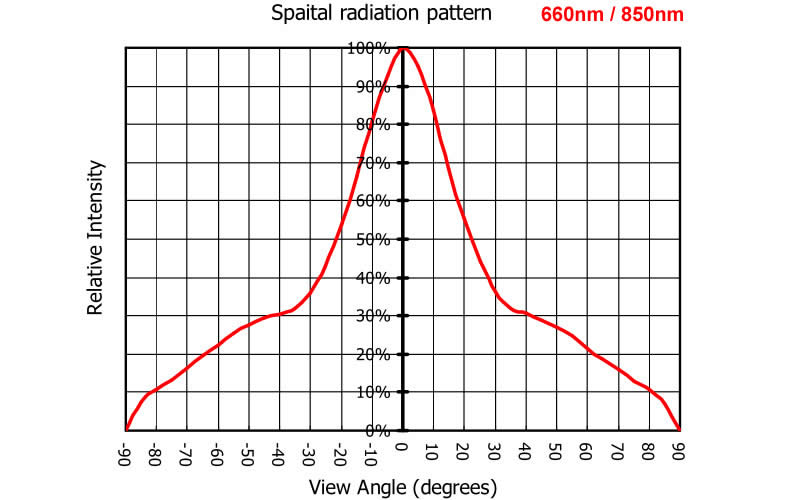

Viewing Anglet Note[1] |

2θ1/2 |

IF=700mA |

50 |

60 |

70 |

Degree |

Parameter |

Symbol |

Conditions |

Min. |

Typ. |

Max. |

Units |

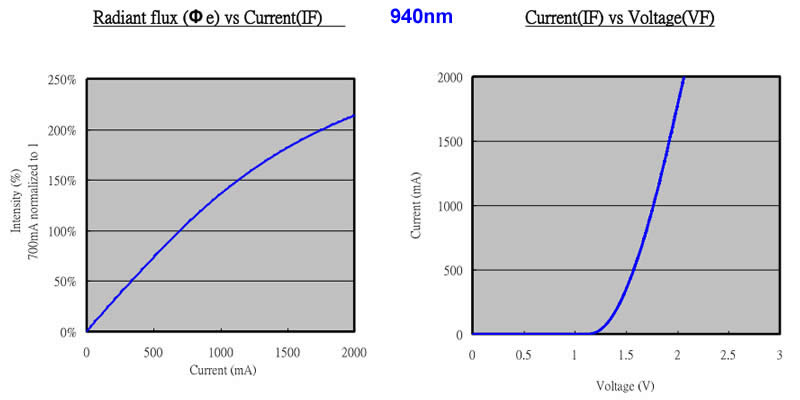

Radiant Flux |

Φe |

IF=700mA |

135 |

760 |

mW |

|

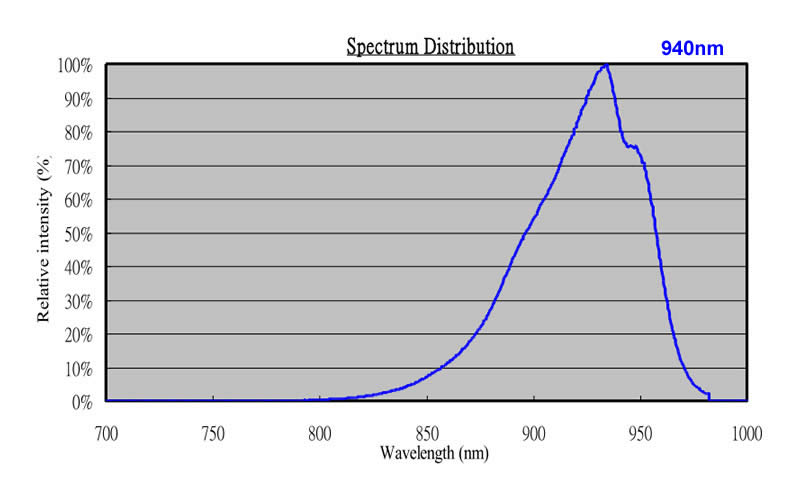

Peak Wavelength |

WLP |

IF=700mA |

935 |

955 |

nm |

|

Forward Voltage |

VF |

IF=700mA |

1.2 |

3.2 |

V |

|

Thermal Resistance JunctionTo Board |

RthJ-B |

IF=700mA |

13 |

°C/W |

||

Temperature Coefficient of Forward Voltage |

ΔVF/ΔT |

IF=700mA |

2 |

mV/°C |

||

Reverse Current |

IR |

VR=5V |

10 |

μA |

||

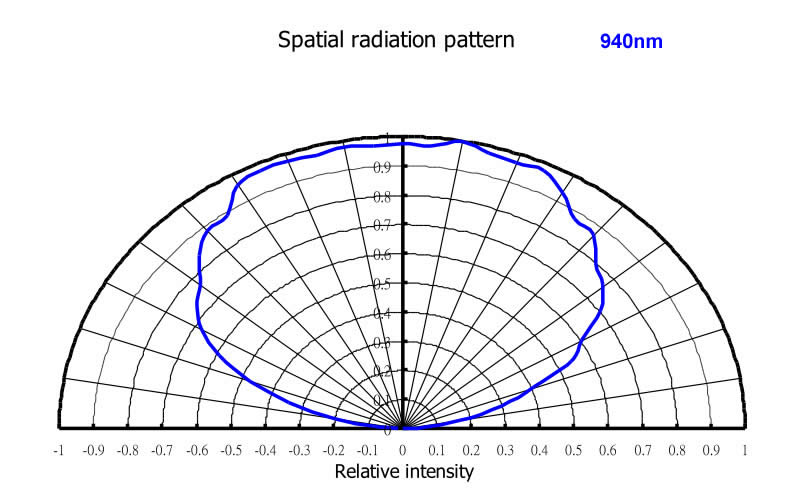

Viewing Angle Note[1] |

2θ1/2 |

IF=700mA |

130 |

140 |

150 |

Degree |

Parameter |

Symbol |

Conditions |

Units |

Power Dissipation |

PD |

3 |

W |

Continuous Forward Current |

IF |

700 |

mA |

Peak Forward Current Note[2] |

IF(Peak) |

1000 |

mA |

LED Junction Temperature |

Tj |

120 |

/°C |

Reverse Voltage |

VR |

5 |

V |

Operating Temperature Range |

Topr |

30°C To +80°C |

|

Storage Temperature Range |

Tstg |

-40°C To +100°C

|

|

Manual Soldering Temperature |

Tsol |

260°C±20°C For 3-5 Seconds

|

|

ESD Sensitivity |

ESD |

2000V HBM |

|

Profile Feature |

Typical parameters |

Average Ramp-Up Rate (Ts max to Tp) |

3 °C/second max. |

Preheat Temperature Min (Ts min ) |

150 °C |

Preheat Temperature Max (Ts max ) |

200 °C |

Time (ts min to ts max ) |

60-180 seconds |

Time maintained above Temperature (TL) |

217 °C |

Time maintained above Time (tL) |

60-150 seconds |

Peak/Classification Temperature (Tp) |

260 °C |

Time within 5 °C of Actual Peak Temperature (tp) |

5 seconds |

Ramp-Down Rate |

6 °C/second max. |

Time 25 °C to Peak Temperature |

8 minutes max. |

W1 |

W2 |

H1 |

H2 |

L |

16.5 |

9.6 |

8.0 |

3.4 |

424.0 |

±0.2 |

±0.2 |

±0.2 |

±0.2 |

±2.0 |

M |

N |

W |

W1 |

H |

K |

S |

Φ330.0 |

Φ99.5 |

24.4 |

29.0 |

Φ13.5 |

10.75 |

2.5 |

±1.0 |

±1.0 |

±1.0 |

±1.0 |

±0.5 |

±0.5 |

±0.5 |

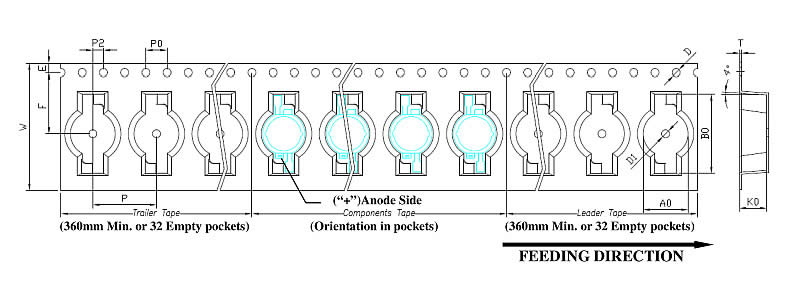

W |

P |

E |

F |

P2 |

D |

D1 |

P0 |

A0 |

B0 |

K0 |

T |

24.0 |

12.0 |

1.75 |

11.5 |

2.0 |

1.5 |

1.5 |

4.0 |

8.45 |

15.0 |

5.10 |

0.37 |

±0.3 |

±0.1 |

±0.1 |

±0.1 |

±0.1 |

±0.1 |

±0.25 |

±0.1 |

±0.1 |

±0.1 |

±0.1 |

±0.02 |

Color |

Order Code |

Peak Wavelength (nm) |

|

Min |

Max |

||

IR

|

UVA-003-660 |

655 |

665 |

UVA-003-850 |

845 |

855 |

|

UVA-003-940 |

935 |

945 |

|